The amplifier is built into a Vox-like cabinet, therefore I used the L-shaped layout of the original.

The advantage of this design is that the tubes and transformers are mounted upright. This makes the whole amp more stable mechanically, especially since the used power transformer is very heavy.

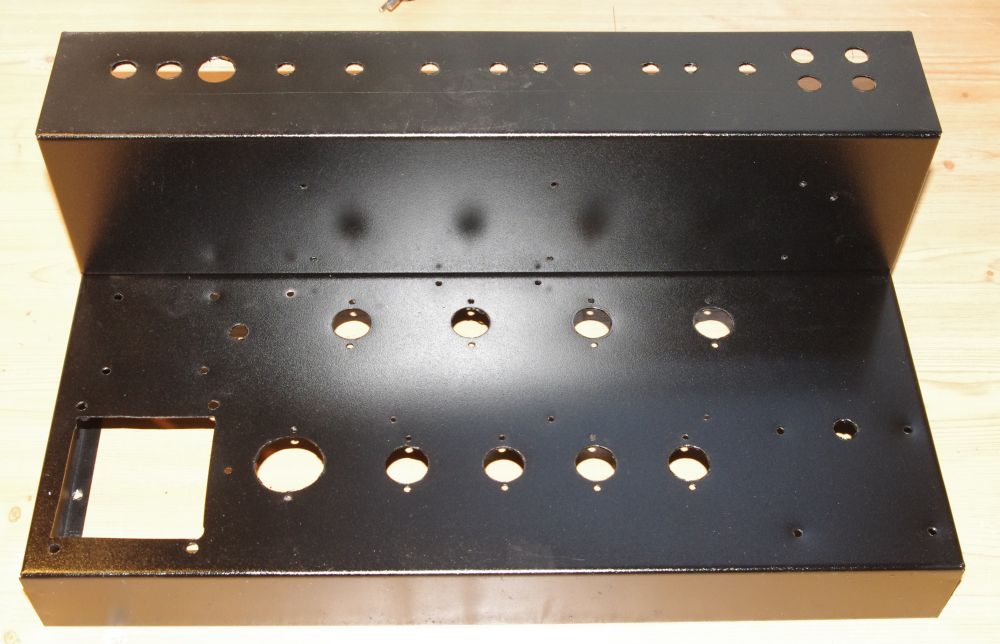

To get a L-shaped chassis, I mounted the main board and the controls into a smaller chassis (Hammond 1441-20), which is fastened to the lower part (Hammond 1441-30) with six M4 screws and nuts.

The first step is to mark the positions for the holes on the chassis parts. The positions are also marked with a centre punch.

The holes are drilled using a bench drill. Smaller holes (up to 12mm) can be drilled with standard HSS metal drill bits. Bigger holes, like the ones for the tube sockets, are pre-drilled and then widened with stepped or cone drill bits.

I used a jigsaw to make the rectangular openings. A file was used to smooth the edges.

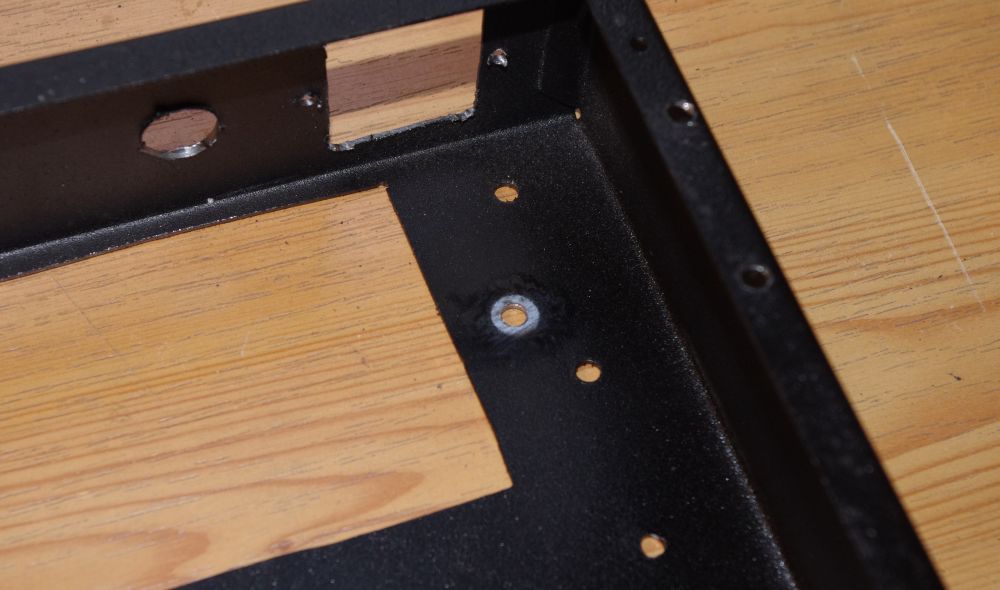

The powder coating of the steel enclosures acts as isolation. As the chassis has to be connected to ground and electrical contact has to be between the chassis parts, the coating has to be removed at some locations.

I did that at the star ground, the attachment screw of the PE and at one fastening screw.

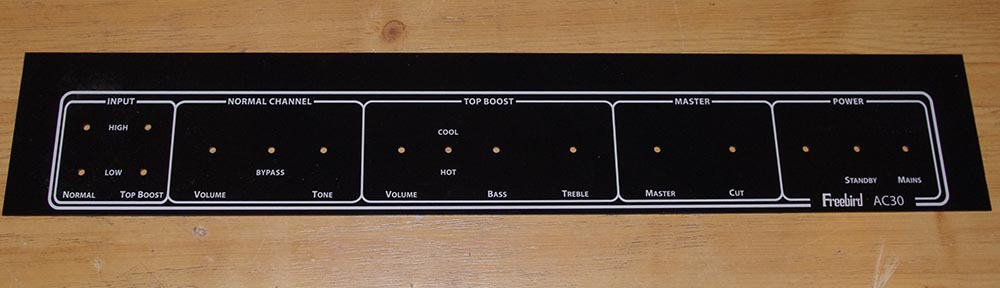

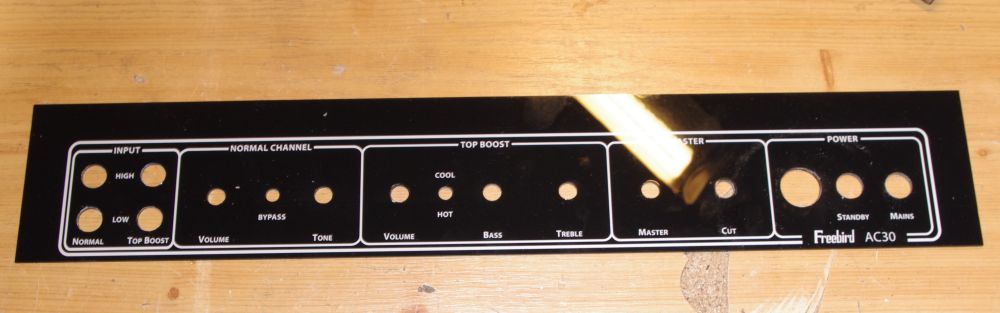

Holes for the controls were first drilled into the faceplate, which was then used as a template for the chassis.

The rectangular openings were also cut into the upper chassis part.

Here are the drilled chassis parts, already screwed together.

The fastening is done with M4 screws, tooth washers and nuts.

The edges of the rectangular openings between the two parts are covered by fabric tape to protect the isolation of the wires, and prevent fraying of the wires.

In this picture the distance bolts, tube sockets and solder terminals are attached. I used Belton-sockets, because they hold the tubes better and also can be soldered more easily than the ceramic sockets. The price difference is negligible for the hobby-builder.

Topside:

Now the boards can be mounted.